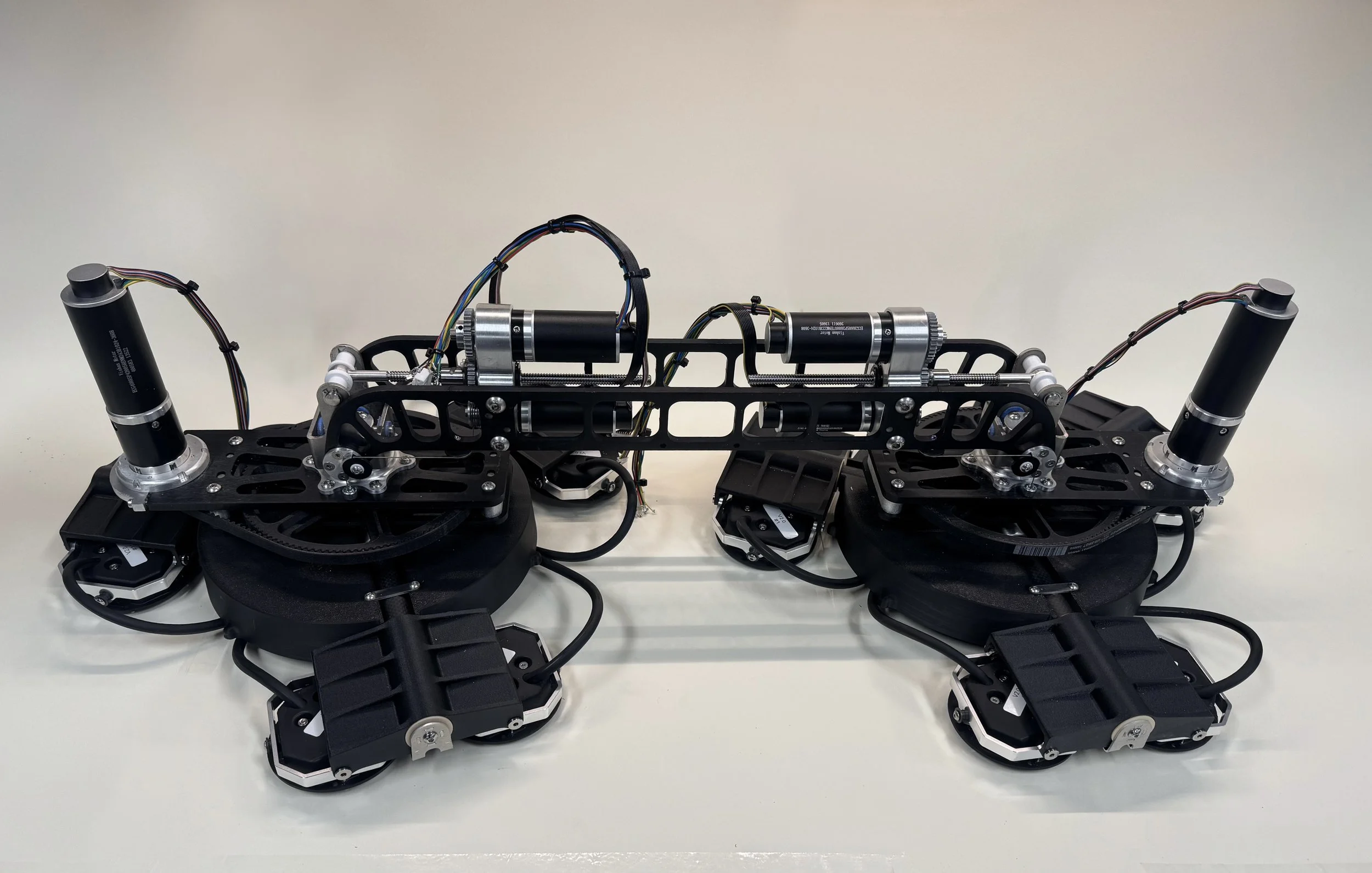

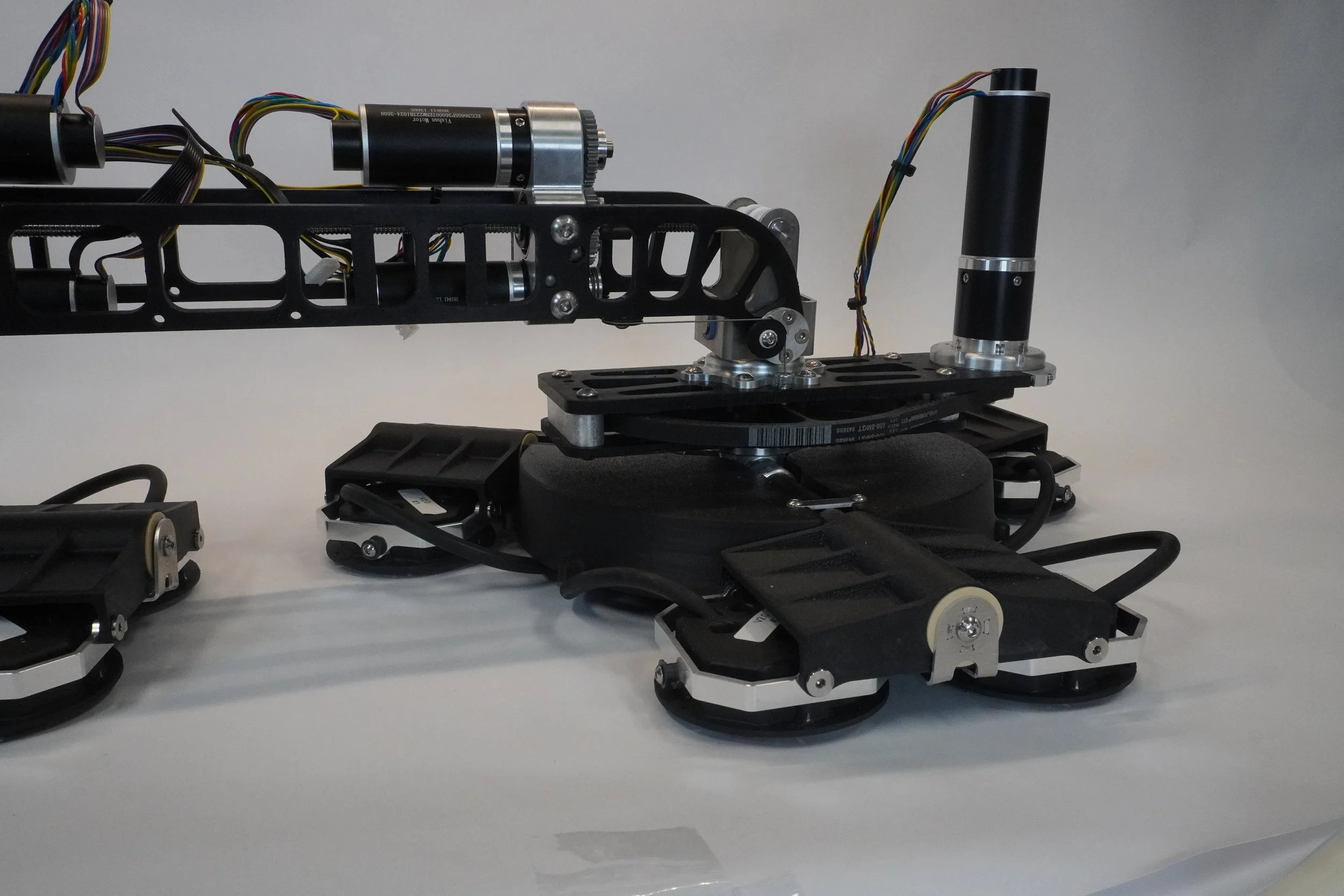

I worked on this project as the lead mechanical engineer at Fleet Robotics, which is developing ship-hull-cleaning robots that would function entirely underwater. The Skeleton Walker serves as a development platform to better understand the dynamics of walking on flat and curved surfaces – but without the added complexity of waterproofing.

We designed the previous version of the robot, V4, to be waterproof from the outset, but found that our waterproofing strategy interfered with the robot's intended mechanics, making it very difficult to design systems with sufficient performance. For example, we initially designed the waterproof housing, assuming we could later design an actuator of sufficient strength. This approach resulted in an extremely complicated system that was difficult to assemble and performed terribly.

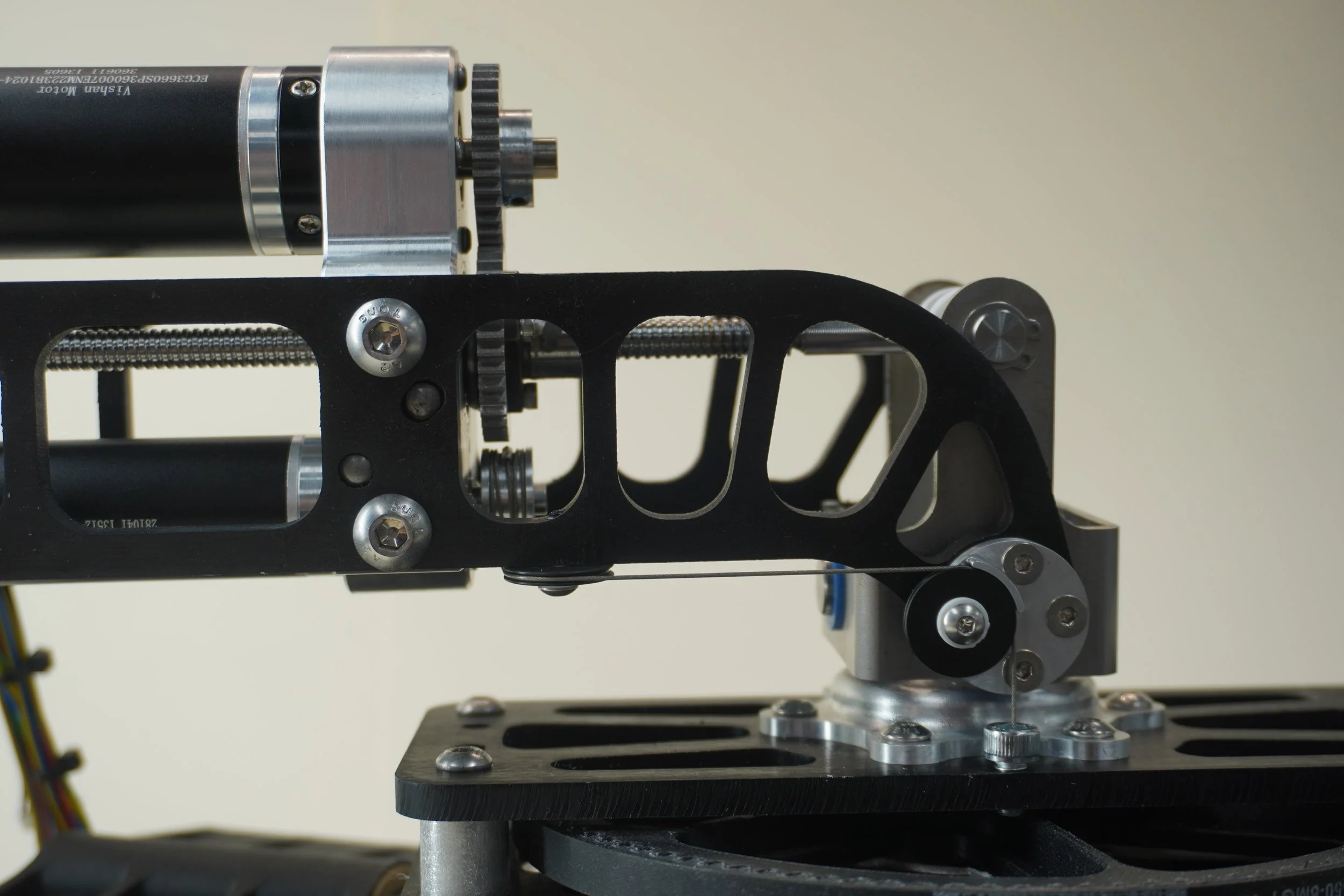

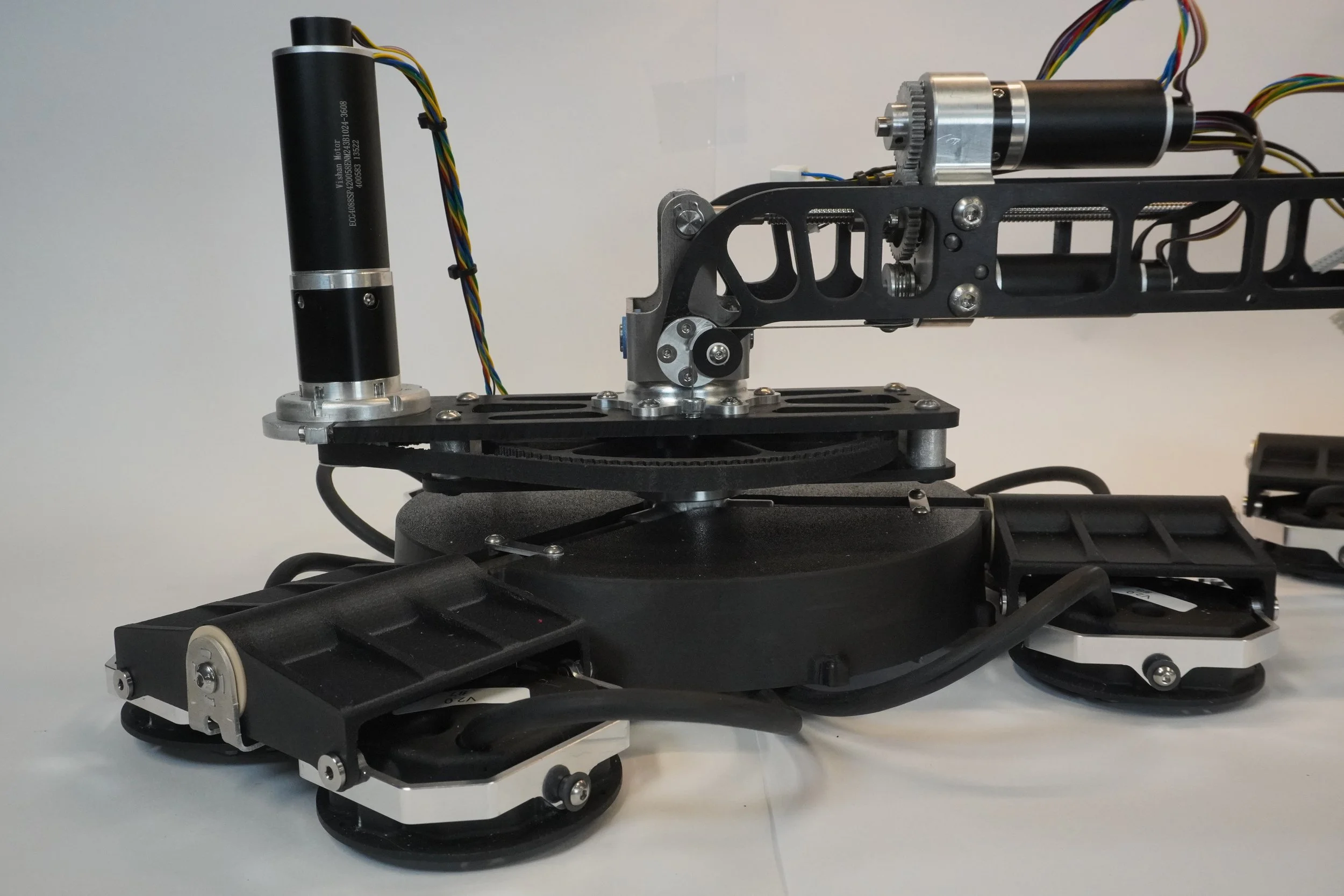

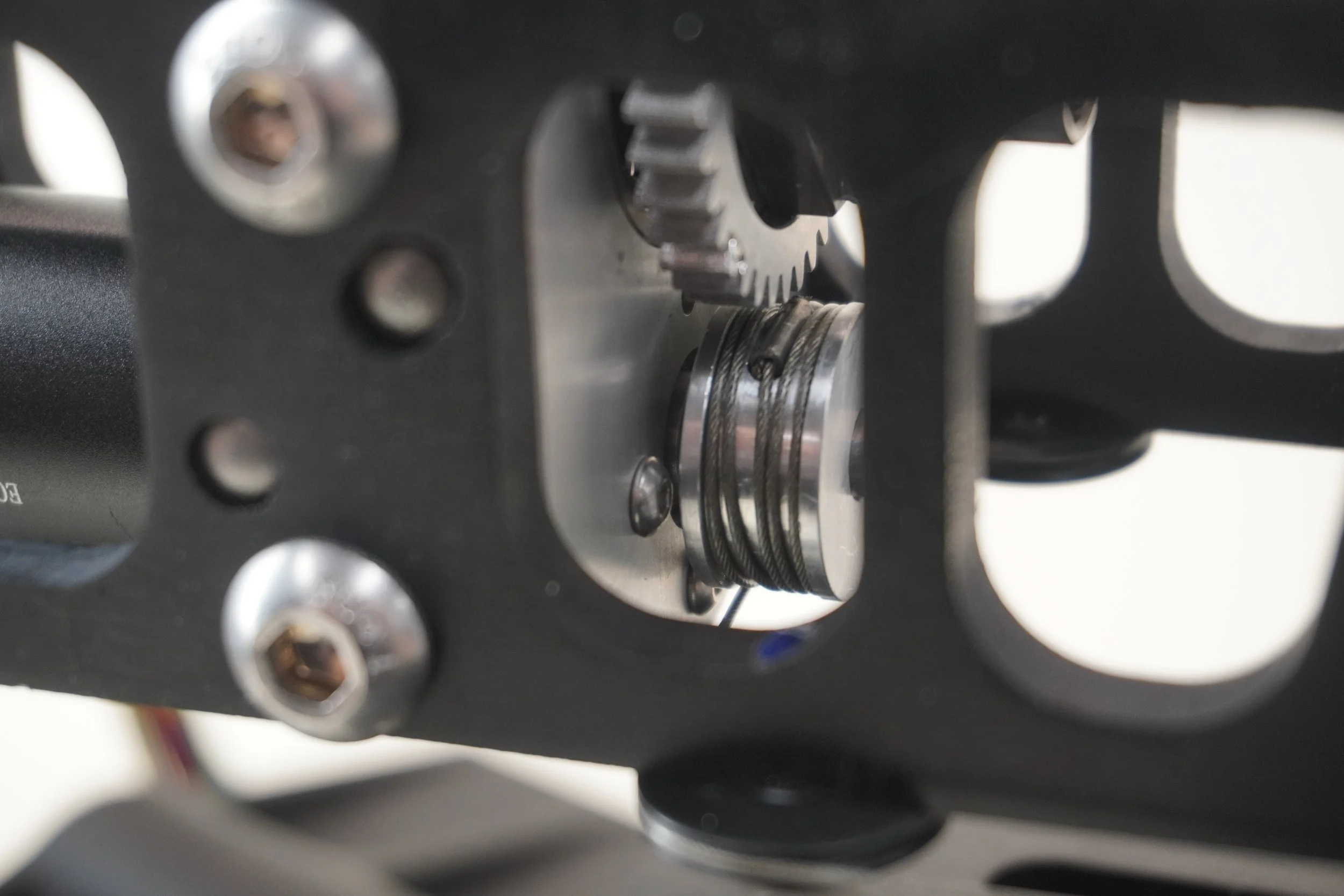

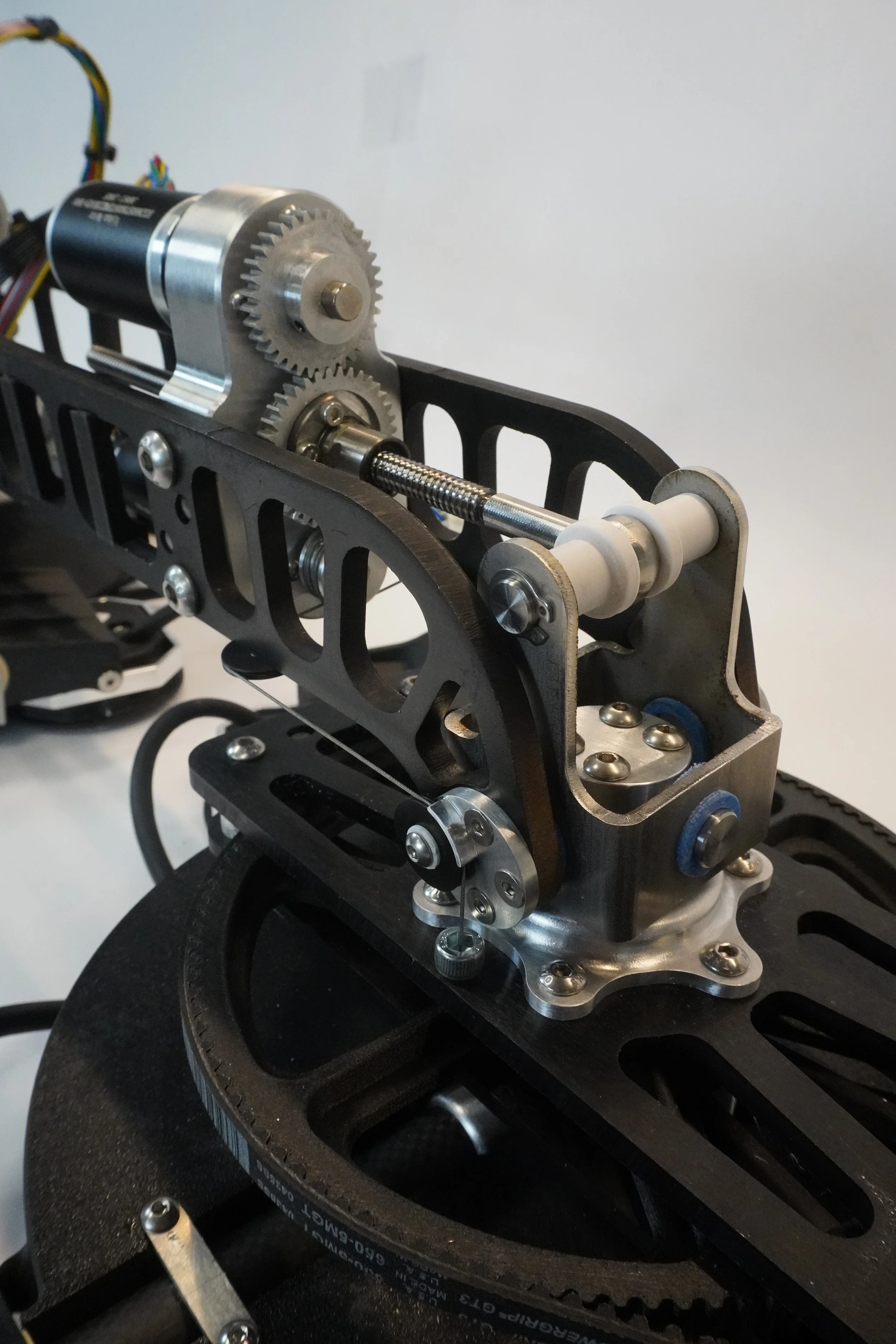

The Skeleton Walker, however, was designed with dynamic movement as its primary functional requirement. This necessitated the use of low gear-reduction ratios due to the N-squared rotor inertia problem. The robot's design incorporates a GT-style belt reduction yaw actuator, a ball screw-based pitch actuator, and a capstan drive with an aircraft cable-driven roll actuator.

Most of the robot's parts are laser-cut and anodized black, while many supporting components are custom CNC-machined aluminum. This project marked the first time I sent a large group of drawings to a CNC machine shop, a process that taught me a great deal about fits and tolerances. One lesson was the importance of switching to a higher grade, more expensive machine shop, as the parts we received from the first shop required significant rework. Once we made that switch for a subsequent set of parts, I was gratified to see that the fits I had meticulously included in the drawings produced the desired results.